Battery Voltage Supervisor DV Power BVS24

SKU: BVS24N-EU-R1

DV Power Battery Voltage Supervisor BVS is a system that monitors battery voltage values during a battery capacity test. The set BVS24 enables voltage supervision of battery string consisting of 24 cells.

Estimated shipping time 4-5 weeks

Battery Voltage Supervisor BVS is a system for monitoring battery cells during a capacity test in order to comply with IEC, IEE and NERC requirements for battery capacity testing. The Battery Voltage Supervisor consists of the following components:

- BVS Control Unit

- Cell Voltage Modules (CVM)

- String Voltage Module (SVM) - optional

- String Current Module (SCM) - optional

Measurement captured by the module are transferred to the Control Unit and to the DV-B Win Software. The BVS-CU also provides power supply to all connected modules.

BVS system can be used together with Battery Load Unit (BLU) series of devices during a battery capacity test to provide information about individual cell condition.

Intended use for BVS

BVS system is intended for real time cell condition assessment by monitoring and recording cell voltages during a battery capacity (discharge) testing or during the charging process.In addition to this, it can monitor cell temperature, intercell connection voltage, string voltage, string current and ambient temperature.

Battery Voltage Supervisor BVS - Key Features

When used together with Battery Load Units (BLU), this system provides multiple advantages during battery capacity testing. The Cell Voltage Modules measure cell voltage values which are saved in the Control Unit in user defined intervals. Out of tolerance measurements are signalized by LED signalization on individual modules so that the failing cells can be easily detected. Failing cells are also marked in red in the DV-B Win software. This enables the user to bypass the failing cell during a capacity test.The control unit is equipped with 4 temperature channels which means that the ambient temperature can be measured in multiple locations. For battery string voltage and string current measurement, additional modules can be used. Using these two optional modules enables the system to work in conjunction with any load bank on the market and perform completely automated capacity test.

Cell temperature (optional) is also possible. Each CVM module can be equipped with a temperature channels where a temperature sensor is connected. The temperature sensor is mounted on the negative terminal of the cell using a lug.

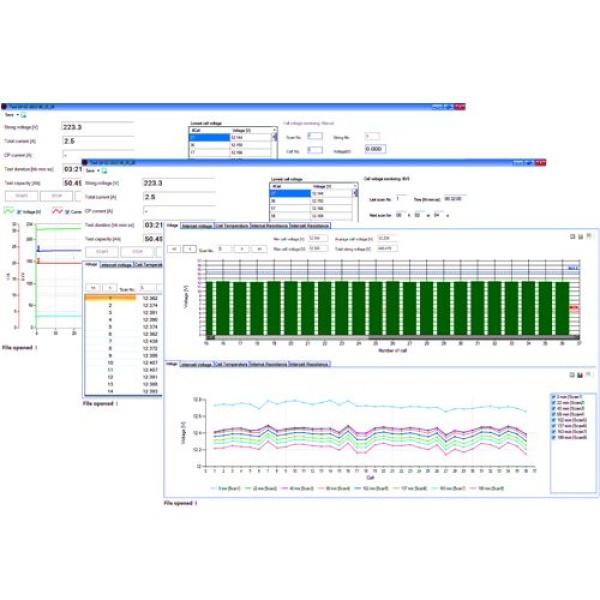

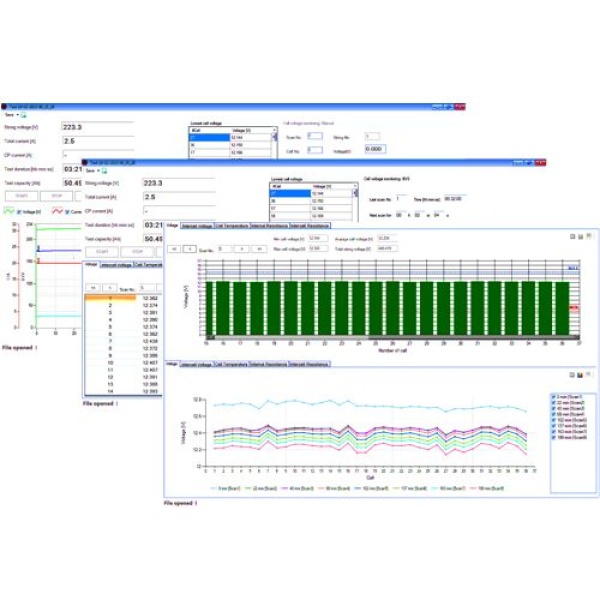

DV-B Win Software

All results transferred from the BVS system can be viewed, analyzed and presented in selectable report forms by using the DV-B Win software application. Data can be transferred to a PC through USB or Bluetooth communication. Both, the BVS and the BLU device provided results can be viewed on the same report form. A quick pass/fail test for a cell values may be performed based on a user defined thresholds, adding additional insight in an individual cell’s status.BVS results can also be imported and combined with a BLU results at a later date using the DV-B Win software and the import BVS log functions.

| Product information | |

|---|---|

| Product name | Battery Voltage Supervisor DV Power BVS24 |

| Brand | DV Power |

| Cell Voltage Measurement | |

| Measurement range | ± 30 V |

| Measurement resolution | 1 mV |

| Typical accuracy | from ± (0,1 % rdg + 0,1 % FS) |

| Intercell Connection Voltage Measurement | |

| Measurement range | ± 50 V |

| Measurement resolution | 1 V |

| Typical accuracy | from ± (0,1 % rdg + 0,1 % FS) |

| String Voltage Measurement | |

| Measurement range | ± 600 V |

| Measurement resolution | 1 mV |

| Typical accuracy | from ± (0,1 % rdg + 0,1 % FS) |

| String Current Measurement | |

| Measurement range | ± 1 A |

| Measurement resolution | 1 A |

| Typical accuracy | from ± (0,1 % rdg + 0,1 % FS) |

| Mains Power Supply | |

| Input voltage | 90 – 264 V AC, 50/60 Hz |

| Input power | 110 VA |

| CVM supply voltage | 66 V DC |

| Data Storage | |

| Storage | Internal SD Card |

| Computer Interface | |

| Interface | USB Bluetooth |

| Environmental Conditions | |

| Operating temperature | -10 ºC – + 55 ºC (+14 ºF – +131 ºF) |

| Storage & transportation | -40 ºC– + 70ºC (-40 ºF – +158 ºF) |

| Humidity | 5 % – 95 % relative humidity |

| Applicable Standards | |

| Installation/overvoltage | CAT II IEC/EN 61010-1 |

| Pollution | degree 2 |

| Low voltage directive | Directive 2014/35/EU (CE Conform) |

| Electromagnetic compatibility | Directive 2014/30/EU (CE Conform) EN 61326-1 CAN/CSA-C22.2 No. 61010-1, 2nd edition, including Amendment 1 |

| Dimensions and Weight | |

| Dimensions (W x H x D) | 180 x 206 x 64 mm (7,1 x 8,1 x 2,5 in) |

| Weight | 0.8 kg (1,8 lbs) |

- BVS device

- Cell Voltage module CVM (24pcs)

- Tape for CVM

- Communication cable for CVM connection 1 x 0,25 m (23pcs)

- Communication cable for CVM connection 1 x 2 m

- Cable bag

- USB cable

- Mains power cable EU 10 A

- Plastic transport case for BVS Control Unit and CVM (max. 30 pcs)

- Voltage sense cables 2 x 0,25 m 1 mm2 with banana plugs + alligator clips (24pcs)

- USB with DV-B Win software

- Temperature sensor with cable 1,5 m

All results measured on the BVS system can be viewed, analyzed and presented in selectable report forms by using the DV-B Win software application. Data can be transferred to a PC through a USB or Bluetooth communication. Both, the BVS and the BLU device provided results can be viewed on the same report form.